Important points

1. Mount and lock hole saw correctly

3. Provide sufficient water cooling

Make sure that hole saw is properly mounted on arbour

If the hole saw is not mounted properly, it is likely to rotate unevenly. This makes control considerably harder and it will lower the quality of the finish.

Screw the hole saw well into the threads on the arbour, then tighten the sliding lock with locking pins in place.

Locking pins must be in place. The threads alone are not strong enough to hold larger hole saws securely.

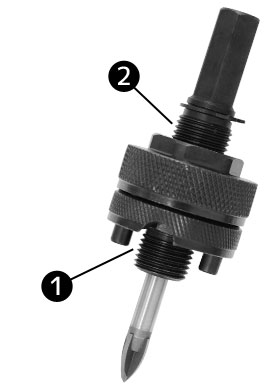

Tighten threads securely on both

❶ hole saw and

❷ locking on arbour

Provide suitable guidance to start the cut – remove when it is not needed anymore

Starting with diamond core drill bits

It is recommended to start with drill bits by holding the bit at a slight angle. First hold the drill bit so that it cuts on one side only, and straighten it when a groove has been made on the surface .

It is advisable to first practice this technique on a scrap piece of material.

In this video

- Starting without using a guide

- Sufficient water cooling

- Suitable speed for core drill bits

Hole saw with pilot drill bit or dedicated guide tool

The arbours for diamond hole saws come equipped with carbide tipped pilot drill bits, which are best suitable for wall tiles and soft stone materials. For extremely hard or thick materials it is better to use a guide, because a pilot drill bit will slow down cutting.

In this video

- Use of pilot drill bit

- Use of guide tool

- Cutting glass

Hole saw with simple board guide

A simple guide can also be made from a piece of board with a hole or a V-shaped edge. The guide or pilot drill should be removed as soon as the cut is deep enough to guide itself.

In this video

- V-shaped guide

- Guide with hole for uneven surfaces

Water cooling is sufficient when the cut does not dry up during work

Water keeps the tool and the workpiece cool, as well as draws out waste material from the cut. With extremely hard materials, such as porcelain tiles or granite, ample cooling with water is essential.

Cutting speed should be set for smooth cutting and low heat

Optimum cutting speed depends on the material and the size of the tool. With harder materials, or when using a larger hole saw, the speed should be correspondingly lower. With large hole saws, it is recommended to use a drill equipped with a separate low speed gear.

Never use hammering action with diamond tools!